What is the difference between a freight elevator and a passenger elevator?

The main differences between a freight elevator and a

passenger elevator are in their design, capacity, and intended use.

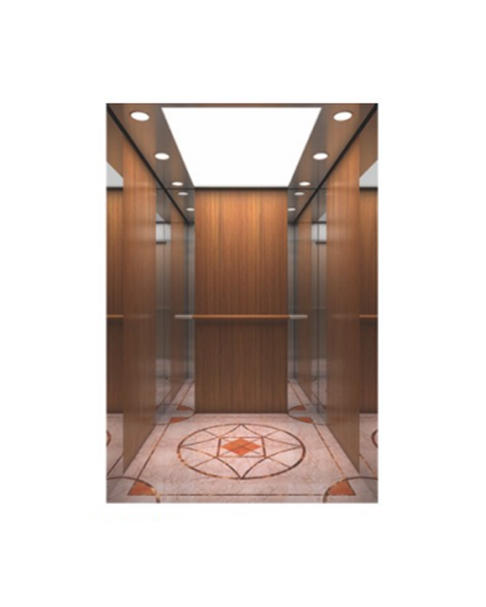

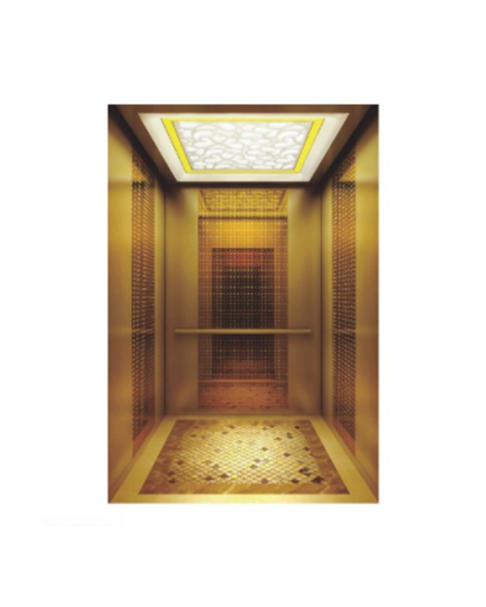

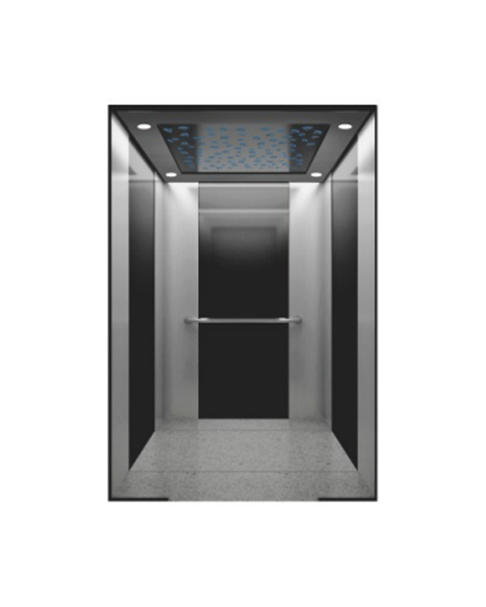

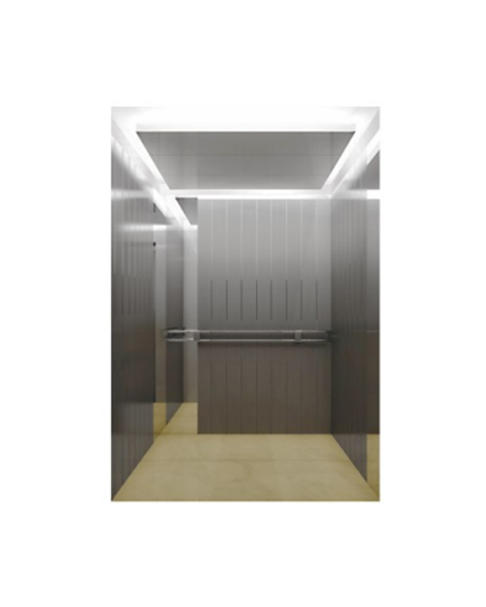

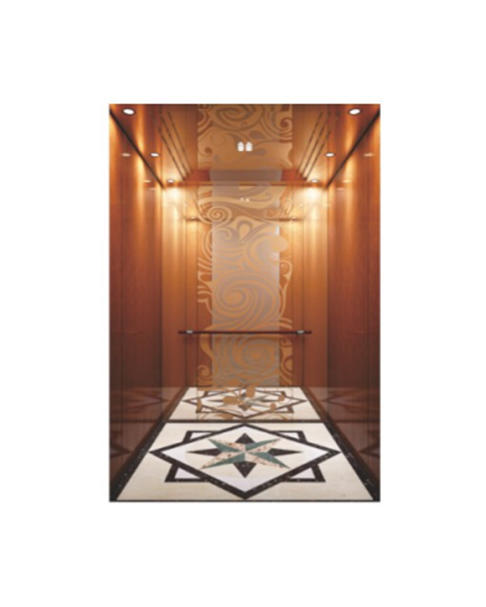

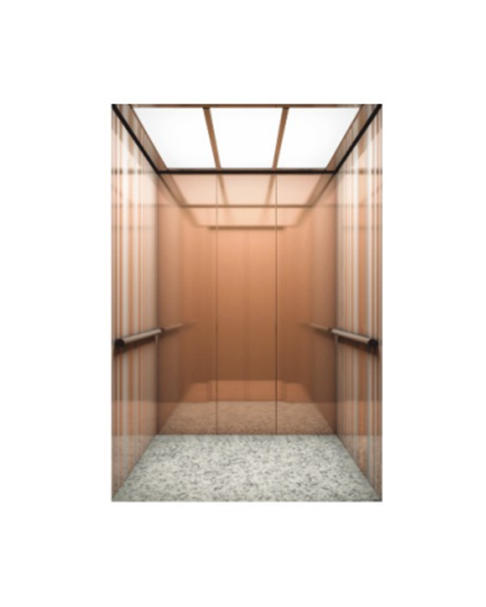

1. Design: Freight elevators are designed to transport heavy loads and are therefore typically larger and more robust than passenger elevators. They may have wider doors, stronger flooring, and more durable materials to withstand the weight and impact of heavy cargo. Passenger elevators, on the other hand, are designed for people and may have more aesthetic features, such as decorative lighting and finishes.

2. Capacity: Freight elevators are generally designed to carry much heavier loads than passenger elevators. They may have weight capacities of several thousand pounds, whereas passenger elevators are typically limited to a few thousand pounds at most. Freight elevators may also have larger car sizes and higher ceilings to accommodate large or bulky items.

3. Intended use: Freight elevators are primarily intended for the transportation of goods and materials, often in commercial or industrial settings. Passenger elevators, on the other hand, are intended for the transportation of people and are found in a variety of settings, including residential and commercial buildings, hospitals, and airports.

While there may be some overlap in the design and capacity of freight and passenger elevators, their intended use and functional differences make their distinct types of elevators.

Here are some general passenger elevator guidelines:

1. Capacity:

Passenger elevators have a maximum capacity, which should be clearly marked. Make sure not to exceed this capacity, as it can be dangerous and may cause the elevator to malfunction.

2. Enter and exit carefully: When entering and exiting the elevator, be careful not to trip or fall. Wait until the elevator has stopped and the doors have fully opened before entering or exiting.

3. Press the correct button: Make sure to press the button for the correct floor or level. If you are unsure, ask for assistance.

4. Don't overload the elevator: Avoid overloading the elevator with too many people or too much weight. This can cause the elevator to become stuck or malfunction.

5. Don't force the doors: If the elevator doors do not open or close properly, do not force them. This can cause damage to the elevator and may also be dangerous.

6. In case of emergency: If you are in the elevator and there is an emergency, use the emergency phone or alarm button to call for help. Do not try to exit the elevator unless instructed to do so by trained personnel.

7. Follow posted guidelines: Be sure to follow any posted guidelines or instructions for using the elevator. These may include rules about food and drinks, behavior, or other safety guidelines.

What is the life of a passenger lift?

The life of a

passenger lift can vary depending on several factors, such as the quality of the equipment, the amount of use, the level of maintenance, and the environment in which the lift is installed. In general, a well-maintained passenger lift can last between 15 and 25 years, although some may last longer.

Regular maintenance is essential to extend the life of a passenger lift. Maintenance tasks can include cleaning, lubrication, inspections, and repairs as needed. Maintenance schedules should be determined by the manufacturer's recommendations, as well as any local regulations or codes that apply.

As a lift ages, it may become less efficient or less reliable and may require more frequent repairs or upgrades. At some point, it may be more cost-effective to replace the lift with a new one rather than continue to maintain an older, less reliable lift.

English

English 简体中文

简体中文 русский

русский Español

Español